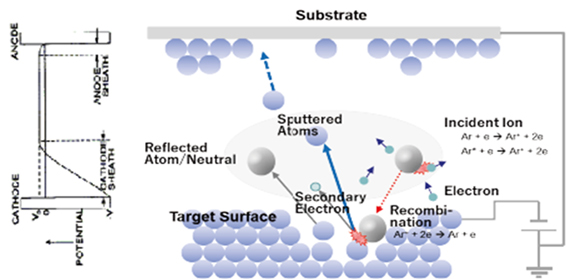

High-energy residual emission and collision/ionization with neutral gas

Ion acceleration due to positive bias near the target / Collision with the target and transferring momentum through the cathode sheath → Total bias (Vp-Vc): 200 ~ 1000eV by IV characteristics

Target leaving the lattice and moving to the substrate: 3~10eV

Secondary electron emission and self-discharge are maintained when ions collide with the target.

Collision of electrons with surrounding gas, generation of radical and negative ions / Impact of acceleration material along the anode sheath

Condensation and thin film formation on the surface of the released target particles

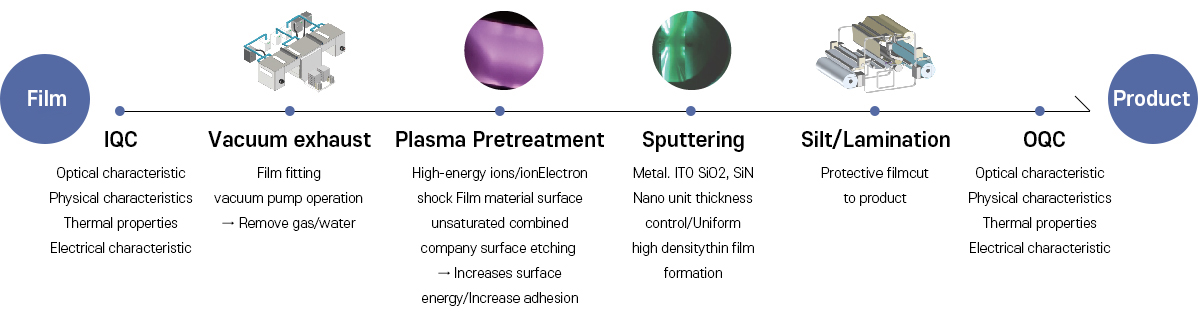

| Effective Width | 400m less then |

|---|---|

| Film Thickness | 25㎛ or more |

| Roll Diameter | 500m |

| Pretreatm ent | Plasma Pretreatm ent |

| Cathode | 1(Single)ea + 1(Dual)ea |

| Sputter Power | DC 1ea + MF 1Set |

| Heating System | IR-Heater / Drum |

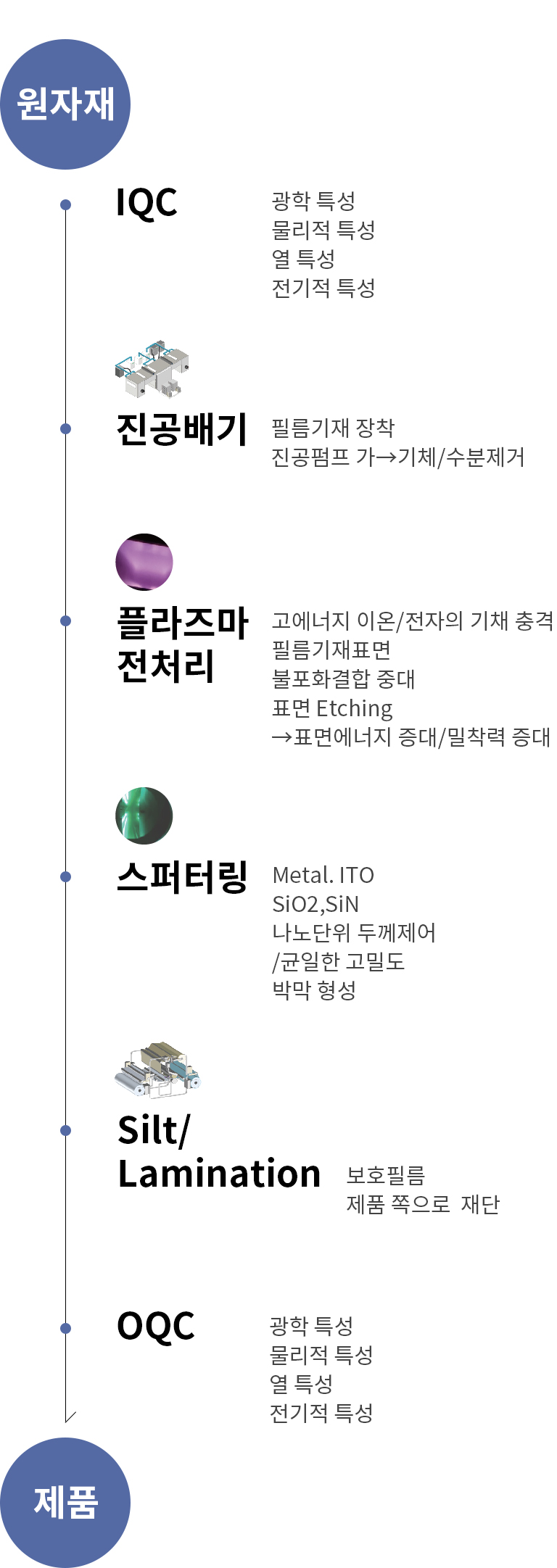

| Deposition effective width | 1500m |

|---|---|

| film thickness | 1500m |

| Film roll diameter | 3000m |

| Installed film length | 3000m |

| film length | < 5.0E-5Pa |

| maximum vacuum | < 5.0E-4Pa |

| Reach input | Plasma treatment (ea) |

| speaker device | 6(Single)ea+1(Dual)ea |

| speaker power | MF(1)ea / DC(6)ea |

| Giza heating device | IR Heater / Drum |

| vacuum pump | Dry Pump+B |

| Four Cold | |

| vacuum chamber | drum/water |

| Film substrate driving device | |

| Plasma pretreatment | |

| TMP / Cryo coil | |

| Sputter device | Cathode (dual) |

| Power output device | |

| Gas supply control |